High‑value beef product from the Pilbara, Australia

In MLA’s ‘Down the track’ series, we catch up with producers who have been profiled in the past to see how their business is evolving in response to new challenges and opportunities.

Looking back

Pardoo Beef Corporation, at ‘Pardoo Station’, WA partnered with MLA Donor Company (MDC) on a collaborative co‑innovation program.

The three‑year program explored the production and economic benefits of different pasture and breeder management systems and global market options to determine how to best utilise Pardoo’s 15‑gigalitre annual water allocation.

The project has presented its share of challenges – from sourcing skilled staff to capturing data in an extensive grazing enterprise – but the first generation of Wagyu bred on Pardoo Station have now reached dinner tables around the world.

Looking ahead

A high‑value beef product might not be the first thing people connect to the vast, dry Pilbara of WA, but Singaporean businessman Bruce Cheung has tapped into the region’s water resources as part of his vision to produce Wagyu for a global market.

By developing water infrastructure to grow year‑round feed and produce boxed beef, he created an alternative to the region’s traditional model of turning cattle off native pastures for live export.

And so, Pardoo Beef Corporation (PBC) was born, targeting a higher‑value market that demands quality and provenance.

The company purchased ‘Pardoo Station’ in 2015 with two existing centre pivots and soon added more as well as a Wagyu herd.

In 2016, PBC embarked on a three‑year Collaborative Innovation Strategy program with MDC to glean knowledge about their innovative beef production model to share with the wider industry.

An early challenge was finding a scientist willing to live in the remote region.

After a year’s quest, MDC and PBC approached Kevin Bell, a former Professor of Animal Production Systems at Murdoch University, to work at Pardoo.

“It wasn’t really what I planned to do at the age of 75, but it was too much of a challenge to let it go,” Kevin said.

“My wife was a bit dismayed, but I’ve made it work. I spend one week in every two or three there collecting data, then come home to Broome and work with good connectivity and access to libraries.”

He said the Pardoo project provided many insights for the wider beef industry.

“It opens up one more market opportunity for the beef industry in this and similar environments.

“No one thought you could put that sort of beef on a table coming out of those harsh conditions.”

Here’s some of the insights from PBC, as it evolves to meet the challenges presented in the Pilbara.

Building a workforce

Pardoo’s irrigation supports year‑round grazing productivity, but this creates a challenge of attracting and retaining staff who are skilled at intensive grazing management in a northern tropical environment.

The high rate of pasture production through summer means human resource requirements to rotate stock through paddocks are greatest at the time of year when, traditionally, staff requirements in northern Australia drop off because of seasonal conditions.

“We record growth rates at the extreme of 300kg/ha/day, so you have to manage the grazing extremely well,” Kevin said.

MLA’s Program Manager – Capability, Josh Whelan, said MLA was committed to addressing the skills base in grazing management.

“A key pillar of MLA’s Strategic Plan 2025 is transitioning to a culture that captures and shares data across every point in the supply chain – investing in people and systems to have the skills to drive decision making,” he said.

“Building innovation capability in grazing management with Pardoo can help showcase to others how to approach solving one of industry’s big, complex challenges.”

Data‑driven decisions

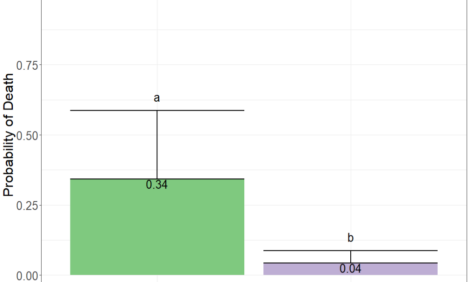

The initial MDC project examined two essential requirements for the intensive

Wagyu production system on irrigated tropical pastures – grazing management and cattle weight gains.

1. Grazing management

The project assessed the rotational grazing system at Pardoo and found grazing intervals varied greatly and were influenced by pasture type, previous grazing history, temperature, fertiliser and water supply.

The project used two grazing management software programs, MaiaGrazing™ and AgriWebb™, to record cattle movements over up to 80 paddocks.

Both were found to have excellent functionality to record and manage stock movements and subsequent paddock performance.

The project also highlighted how collecting additional data, such as crop water use, supplementary feeding, genetics and feedlot and market performance, would be valuable for decision making.

This paved the way for a second three‑year project – which began in 2020 – to get a clearer picture of PBC’s cost of production through digital infrastructure and data management.

Although it varies with the age of cattle and time of year, the cost of production at Pardoo ranges from $2.50–$4.50/kg. PBC will draw on this second project to make operational adjustments to hit an optimal cost of production of $2.50–$3/kg.

2. Weighing

Cost of production at Pardoo was calculated using weight gain and input costs.

Initially, the project team found that moving cattle to a number of robust, fixed, strategically located yard facilities with either permanent or mobile scales was the most efficient way to frequently weigh cattle of variable mob sizes and types.

However, a downside of this approach was handling stock in extreme temperatures.

To overcome this, PBC have now installed walk‑over weighing systems to generate automatic data.

Development

PBC has plans to continue developing water infrastructure as well as build its herd of Wagyu cattle which are bred for the harsh Pilbara and Kimberley environments and selected for hardiness and reproductive and eating quality traits.

Lessons learned

- Source a range of advice and look beyond the beef industry for ideas.

- Don’t rush change – understand the cost of production and required skill base first.

- When managing tropical grass, profitability requires precise management.

- Regularly record cattle weights to detect problems early.

TheCattleSite News Desk