Keeping chocolate milk smooth, stable without carrageenan

Fat-free chocolate milk processed for the first time with high-pressure jet technology exhibits enhanced viscosity, stabilizing cocoa particles in the fluid and eliminating the need for adding a controversial emulsifier.

That’s the conclusion of a team of Penn State researchers, whose study suggests that the new technology can preclude the use of carrageenan in chocolate milk. The widely used food additive — which helps keep the liquid smooth and well-mixed even after days sitting on a store shelf — is not desired by many consumers, especially in organic chocolate milk.

Although the U.S. Food and Drug Administration has approved the use of carrageenan, concerns about its safety remain, according to team leader Federico Harte, professor of food science at Penn State University. He noted that some scientists believe that the additive — a compound extracted from red seaweed — can cause inflammation and digestive problems such as bloating and irritable bowel disease. As a result, the additive is banned in infant formula in the European Union.

“This research is not about being against carrageenan — it’s about consumers wanting clean food labels with only ingredients they recognize,” he said. “And carrageenan definitely is not something they want in chocolate milk. We know that USDA has considered banning it for organic chocolate milks. Our results indicate that would be possible.”

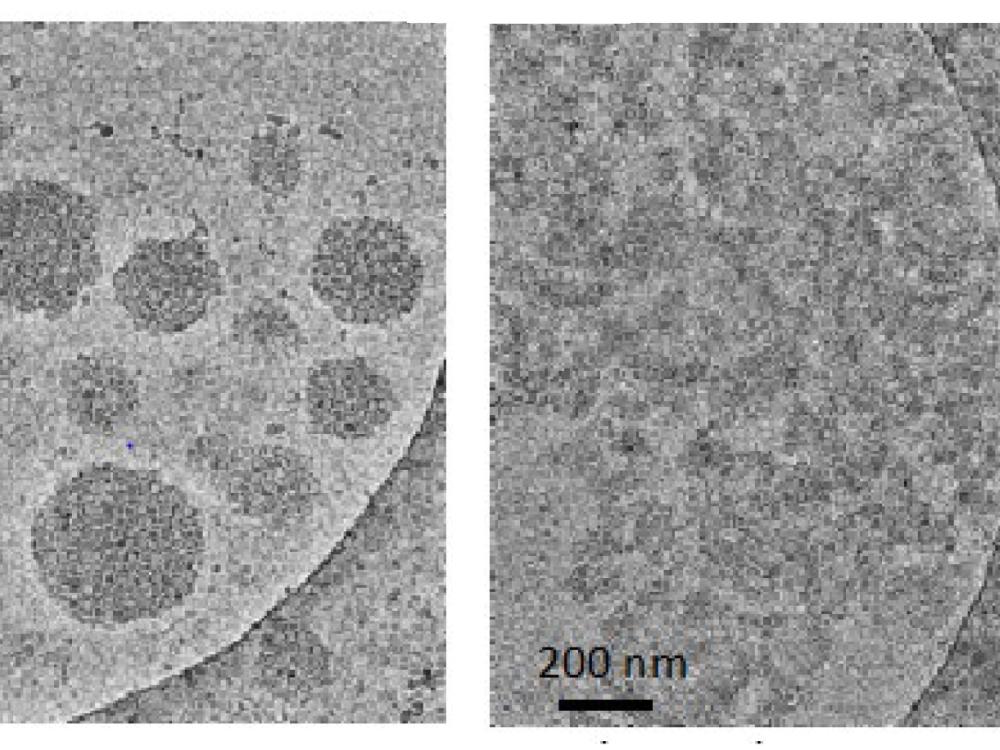

In the study, researchers thermally treated fat-free chocolate milk formulations containing skim milk, cocoa powder and sugar and then processed them using high-pressure jet technology from 125 to 500 megapascals. The viscosity, flow properties and stability of chocolate milks treated with high-pressure jets were compared with chocolate milks that did not undergo high-pressure jet processing, prepared both with and without adding carrageenan.

As expected, carrageenan-free chocolate milk exhibited immediate phase separation of the cocoa powder, whereas formulations containing carrageenan were stable for 14 days, with cocoa particles not dropping out of suspension. However, the researchers observed increased stability with increasing jet processing pressure, with maximum stability achieved when chocolate milk was processed at 500 megapascals.